Intshayelelo:ekubeni i-zeroing iseti xa isixhobo somatshini sidityanisiwe okanye sicwangcisiwe, indawo yolungelelwaniso engu-zero yindawo yokuqala yecandelo ngalinye leleyile. Ukuqaliswa kwakhona kwe-lathe ye-CNC emva kokuba umsebenzi ucinyiwe kufuna ukuba umqhubi agqibezele ukusebenza kwe-zeroing, ekwayindawo yolwazi ekufuneka yonke i-CNC processing practitioner iqonde. Eli nqaku liza kwazisa ubukhulu becala intsingiselo ye-zeroing CNC lathe.

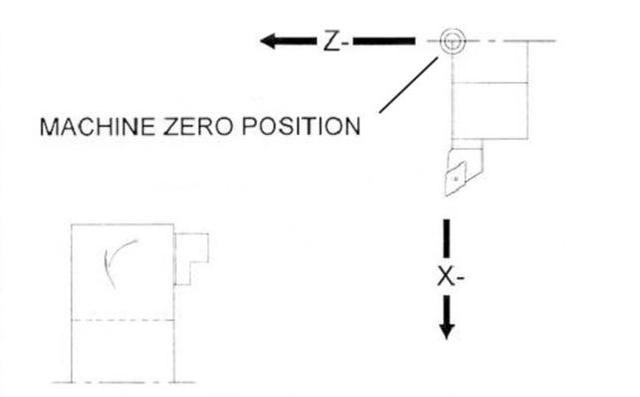

Ngaphambi kokuba i-lathe ye-CNC iqalise ukucubungula iinxalenye, abaqhubi bayo kufuneka babeke indawo ye-zero ye-lathe, ukuze i-lathe ye-CNC yazi ukuba iqale phi. Indawo yokuqala yinkqubo ye-zeroing esetyenziswa kwiprogramming. Zonke ii-lathe offsets zokuqala zisekwe kulungelelwaniso lwe-zero. Le offset ibizwa ngokuba yi-geometric offset, emisela umgama kunye nesalathiso phakathi kolungelelwaniso lwe-zero kunye nendawo yesalathiso yesixhobo. Eli nqaku lereferensi yindawo nje emiselweyo yesixhobo ngokwaso.

Emva kokuba i-lathe ye-CNC ichanekileyo i-zeroed kwaye umda othambileyo usetiwe, i-CNC Lathe ayiyi kuchukumisa umyinge wokutshintsha ngokomzimba. Ukuba nangaliphi na ixesha kukhutshwa umyalelo wokuhambisa i-CNC lathe ngaphaya kwemida ethambileyo (xa ivuliwe), impazamo iya kubonakala kumgca wesimo kwaye ukunyakaza kuya kumisa.

Yintoni i-zeroing ye-CNC lathe

Iileyile zala maxesha ze-CNC zisebenzisa ikhowudi ejikelezayo eyongezelekayo okanye irula eyongezelekayo yokugawula njengenxalenye yengxelo yokubona indawo. Baya kuphulukana nememori yendawo nganye yolungelelwaniso emva kokuba i-lathe ye-CNC icinyiwe, ngoko ke ixesha ngalinye uqala umatshini, kufuneka uqale ubuyisele i-axis yolungelelwaniso nganye kwindawo emiselweyo yeleyile kwaye uphinde umise inkqubo yolungelelwaniso lwelathe.

I-NC lathe zeroing ngokwenene i-benchmark ehambelana no-0 kunye no-0 ulungelelaniso kwimidwebo ye-CAD, esetyenziselwa ukudala ikhowudi ye-G kunye nokugqiba omnye umsebenzi wekhamera. Kwinkqubo yekhowudi ye-G, u-x0, u-Y0 kunye no-Z0 bamele i-zeroing position ye-NC lathe. Umyalelo wekhowudi ye-G ngumyalelo oxelela i-CNC lathe ukuba yenze ntoni kwinkqubo yomatshini kunye nokusika, kubandakanywa nokukhokela i-spindle ukuhamba umgama othile kwi-axis nganye. Zonke ezi ntshukumo zifuna indawo yokuqala eyaziwayo, oko kukuthi, ulungelelwaniso lwe-zero. Inokuba naphi na kwindawo yokusebenzela, kodwa u-x/y uqhele ukusetwa njengenye yeekona ezine zecwecwe, okanye umbindi womsebenzi, kwaye indawo yokuqala ka-Z iqhele ukusetwa njengemathiriyeli ephezulu yecwecwe okanye emazantsi ezinto zokusebenza. Isoftware yeCAD iya kuvelisa ikhowudi ye-G ngokweziro ezinikiweyo zolungelelwaniso.

Ezi ngongoma azikhankanywanga ngokuthe ngqo kwinxalenye yenkqubo. Njengomsebenzisi we-CNC lathe, kufuneka wazi apho ulungelelwaniso lwe-zero luphi kwaye iphi indawo yesalathiso yesixhobo. Itheyibhile yokuseta okanye itafile yesixhobo ingasetyenziselwa le njongo, kwaye umgaqo-nkqubo wenkampani osemgangathweni unokuba sesinye isibonelelo. Kukwaluncedo ukucacisa imilinganiselo ecwangcisiweyo. Ngokomzekelo, ukuba umlinganiselo ovela ngaphambili ukuya kwigxalaba elisondeleyo uchazwe njenge-20mm kumzobo, umqhubi unokubona i-2-20.0 kwiprogram ukufumana ulwazi malunga nezicwangciso eziphambili.

Yintoni ekufuneka ithathelwe ingqalelo xa i-lathe ye-CNC ivaliwe

Inkqubo ye-zeroing ye-CNC lathe iqala kwi-axis engu-Z, emva koko i-axis ka-x, kwaye ekugqibeleni i-Y. I-axis nganye iya kubaleka ukuya kwiswitshi yayo yomda ide ibandakanye iswitshi, kwaye emva koko iya kubaleka kwicala elichaseneyo de utshintshelo lukhuphe. Nje ukuba zontathu ii-axes zifikelele kumda wokutshintsha, izixhobo ze-lathe ze-CNC zinokubaleka kubude bonke be-axis nganye.

Oku kubizwa ngokuba sisindululo sereferensi yeCNC lathe. Ngaphandle kwesi siphakamiso sereferensi, i-CNC Lathe ayiyi kuyazi indawo yayo kwi-axis yayo kwaye ayinakukwazi ukuhamba emva naphambili phezu kobude bonke. Ukuba i-lathe ye-CNC iyema phakathi koluhlu lokuhamba lonke kwaye akukho xhulumaniso, nceda uqinisekise ukuba yonke i-zeroing igqityiwe kwaye uzame ukuqhuba kwakhona.

Into ebalulekileyo ekufuneka uyiqaphele kukuba ukuba nayiphi na i-axis ibaleka kwelinye icala lokutshintsha komda wayo xa ibuyela ku-zero, nceda ujonge ukuqinisekisa ukuba umyinge wokutshintsha awubandakanyekanga kwindawo ye-NC lathe. Zonke iinguqu zomda zikwisekethe enye, ngoko ke ukuba ufuna ukuvumela i-CNC lathe kunye ne-y-axis limit switch icinezelwe, i-z-axis iya kuhamba kwicala elichaseneyo. Oku kwenzeka ngenxa yokuba izixhobo ze-lathe ze-CNC zihamba ngesigaba se-zeroing, xa sibuya kwi-switch de sichitha. Ngenxa yokuba iswitshi ye-y-axis icinezelwe, i-z-axis iya kuzama ukuhamba ngokungenasiphelo, kodwa ayinakuze ikhuphe.

Eli nqaku ikakhulu lazisa intsingiselo ye-NC lathe zeroing. Ukukhangela isicatshulwa esipheleleyo, unokuqonda ukuba i-NC lathe zeroing ngokwenene i-benchmark ehambelana ne-0 kunye ne-0 yokulungelelanisa kwimidwebo ye-CAD, esetyenziselwa ukudala ikhowudi ye-G kunye nokugqiba omnye umsebenzi wekhamera. Kwinkqubo yekhowudi ye-G, x0, Y0, Z0 imele indawo ye-NC lathe zeroing.

Ixesha lokuposa: Jul-19-2022